Blackstock Aerospace

Additive Manufacturing for Remote Aviation

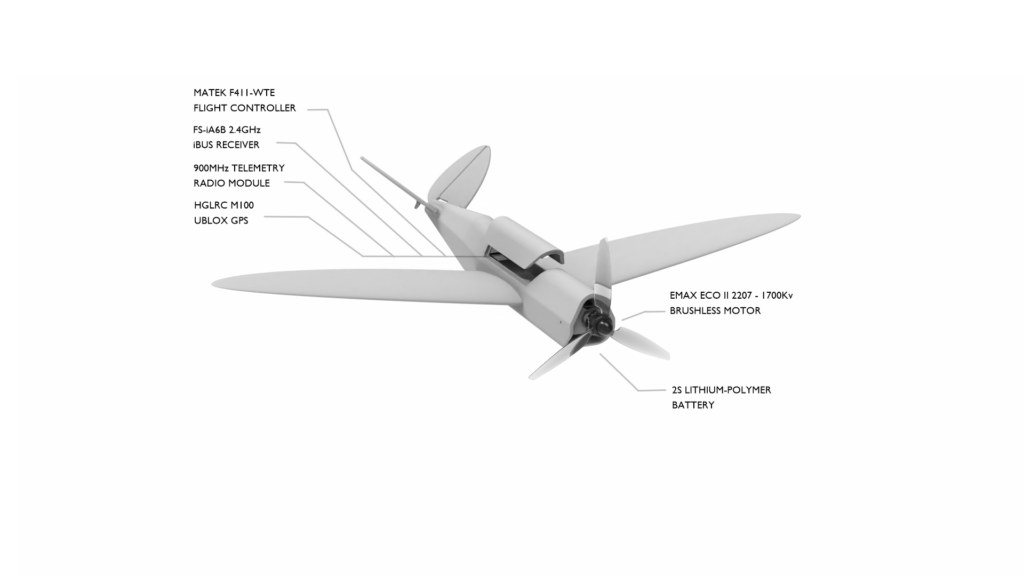

Welcome to my portfolio. Here, I present a detailed exploration of my pet project developing an autonomous drone — working title: “Stingray”. The airframe is primarily made from PLA, chosen for its ease of printing and rigidity, with critical areas reinforced with TPU to improve shock absorption.

The drone is controlled by a Matek F411-WTE flight controller running INAV 7.0. Key components include the FS-iA6B 2.4GHz iBUS Receiver for reliable communication, a 900MHz Telemetry Radio Module for long-range data transfer, and a HGLRC M100 UBLOX GPS for navigation.

It is powered by an EMAX ECO II 2207 – 1700Kv Brushless Motor and a 2S Lithium-Polymer battery, balancing power with efficiency. This portfolio provides an in-depth look at the integration of these technologies into a functional and versatile drone design.

Explore the sections below for more insights into this project.

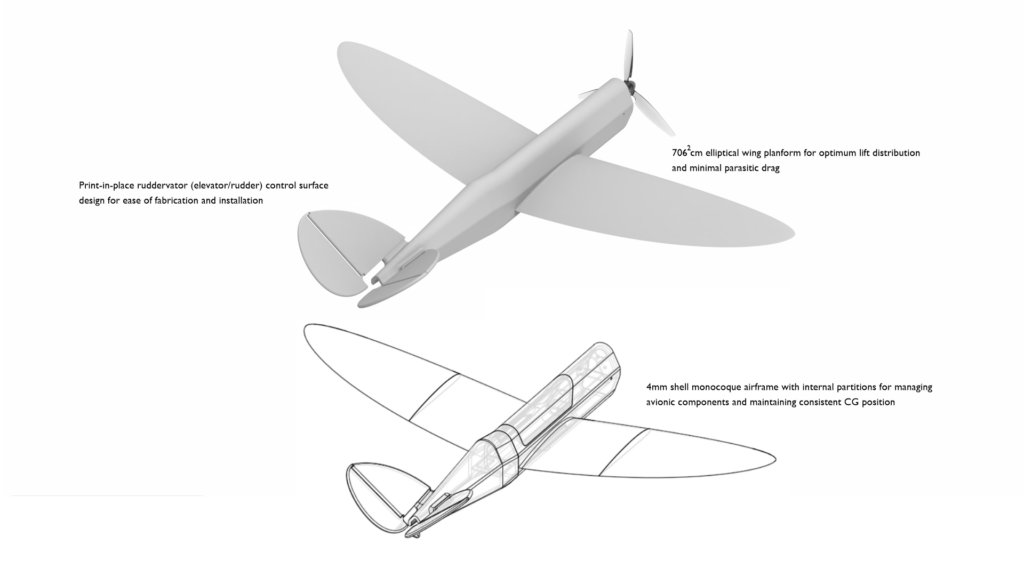

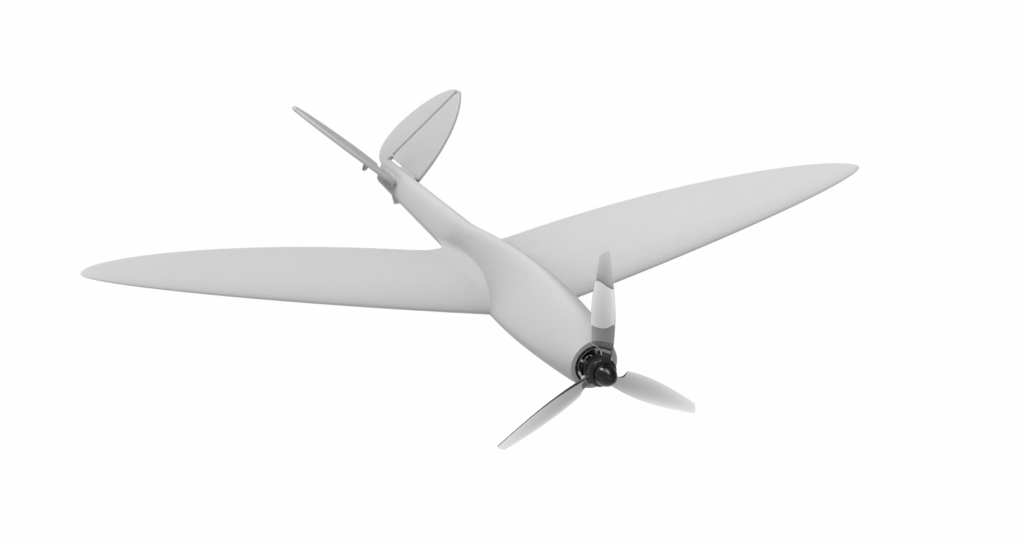

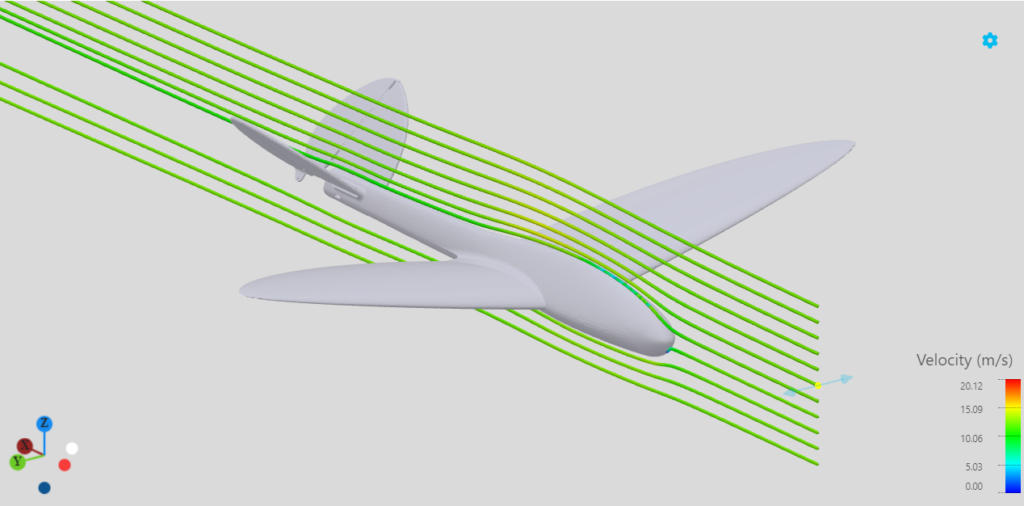

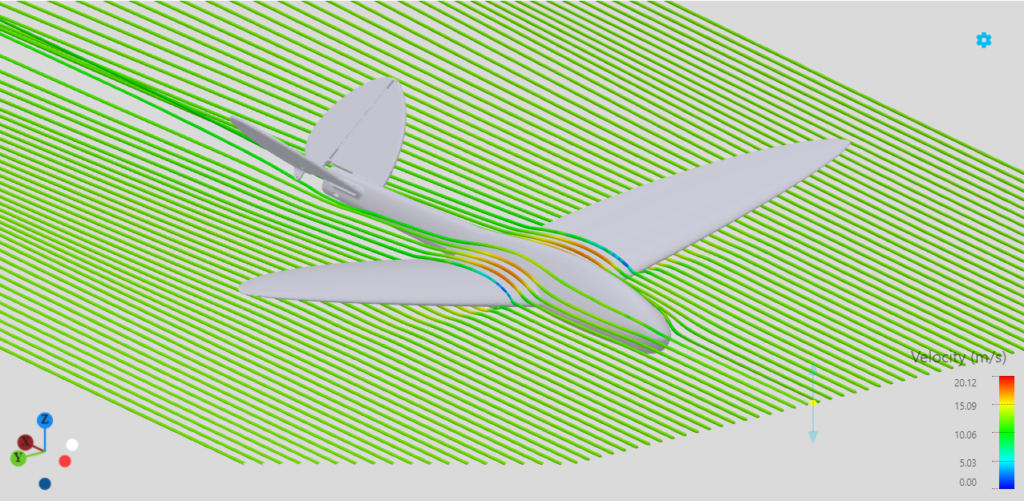

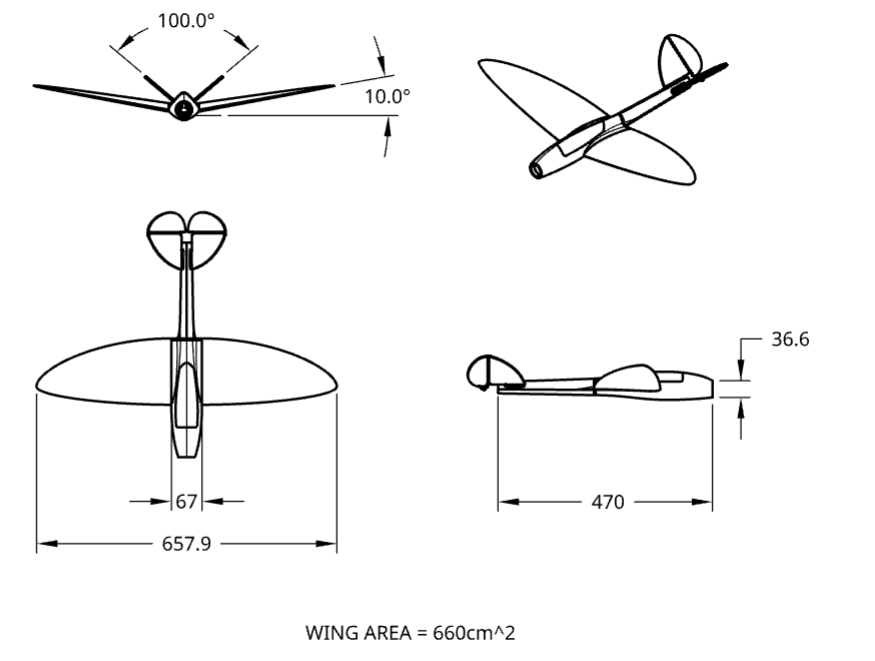

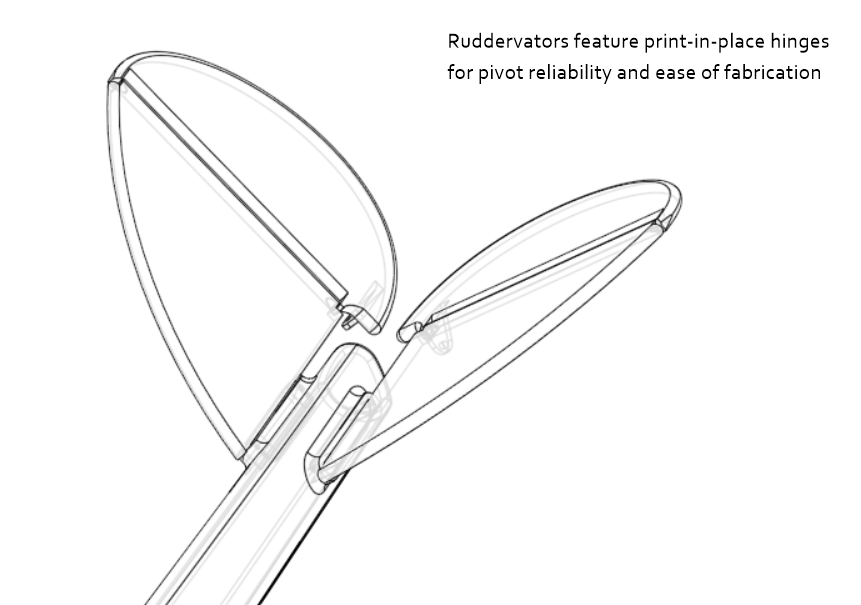

I started developing a secondary design, tentatively called “Sparrow” — a simplified, streamlined version of the Stingray. In its CAD design, I used more advanced surface modeling techniques, resulting in the smooth, continuous curvature shown below.

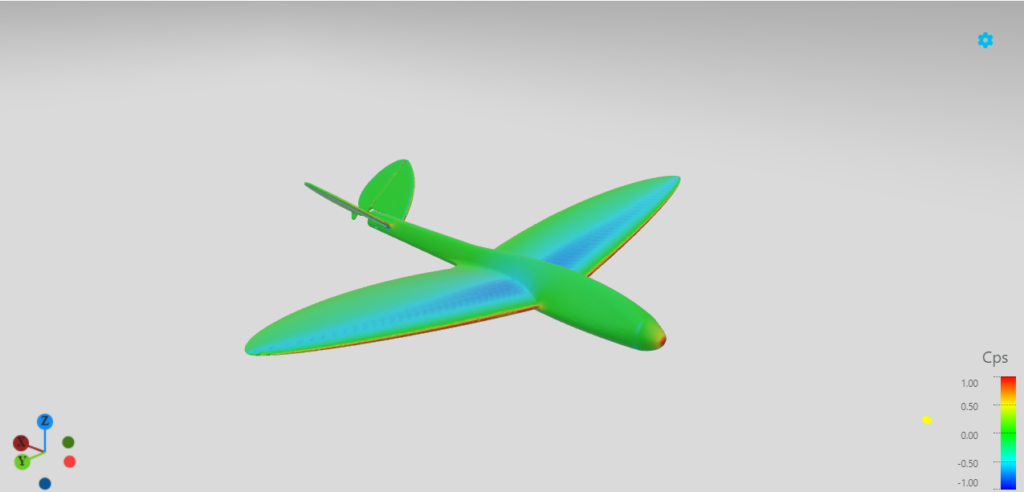

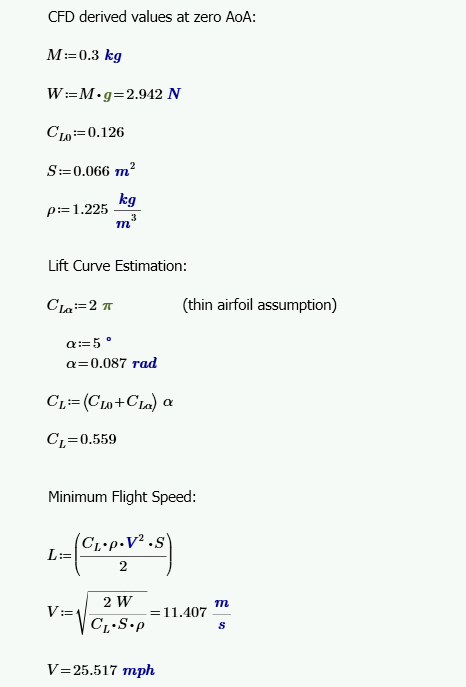

Can’t have an aeronautics project without a little CFD…

Nice to see the pressure differential validate the airfoil selection (NACA 4410).

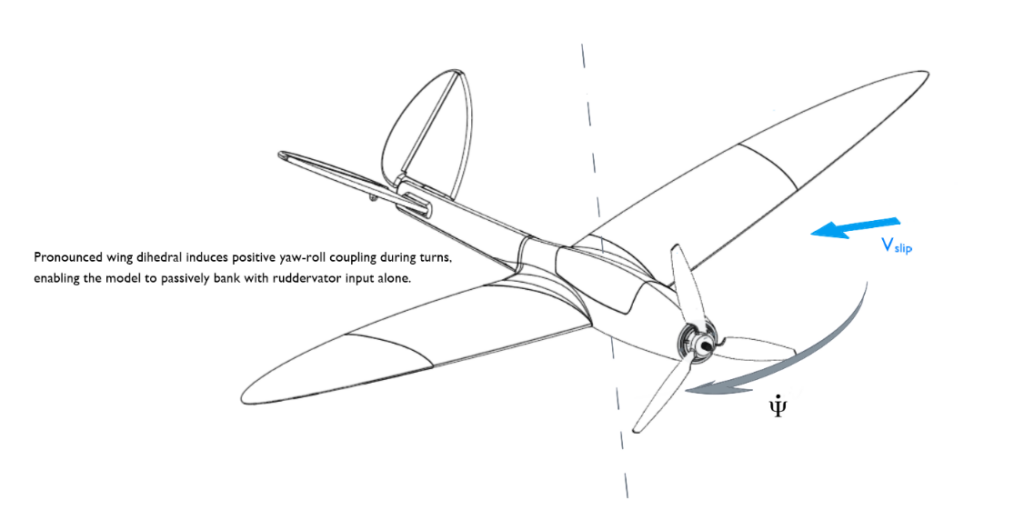

The dihedral effect refers to the self-stabilizing behavior of an aircraft where the wings are angled upward from the root to the tip. This design feature enhances the aircraft’s roll stability and its ability to self-correct in response to side-slip conditions.

When an aircraft with dihedral wings encounters a side-slip (such as from crosswind or turbulence), the lower wing (the one on the side to which the aircraft is slipping) experiences an increase in effective angle of attack and, consequently, an increase in lift compared to the higher wing. This increased lift on the lower wing generates a rolling moment that counteracts the initial slip, helping the aircraft to return to level flight without pilot input.

In an aircraft with a dihedral wing and ruddervators, applying yaw can indirectly control roll. When the ruddervators induce a yaw, the resulting side-slip increases the lift on one wing due to the dihedral angle, thus creating a roll moment. This coupling allows a pilot to effectively control the plane’s orientation using just the ruddervators.

When designing an RC plane that uses dihedral for yaw-roll coupling to achieve roll control through ruddervators alone, one is faced with the challenge of requiring a significant dihedral angle to ensure adequate roll response from yaw inputs. However, an overpronounced dihedral that overpowers directional stability can result in Dutch Roll — a type of oscillatory instability in which the plane erratically gyrates in response to both yaw and roll disturbances.

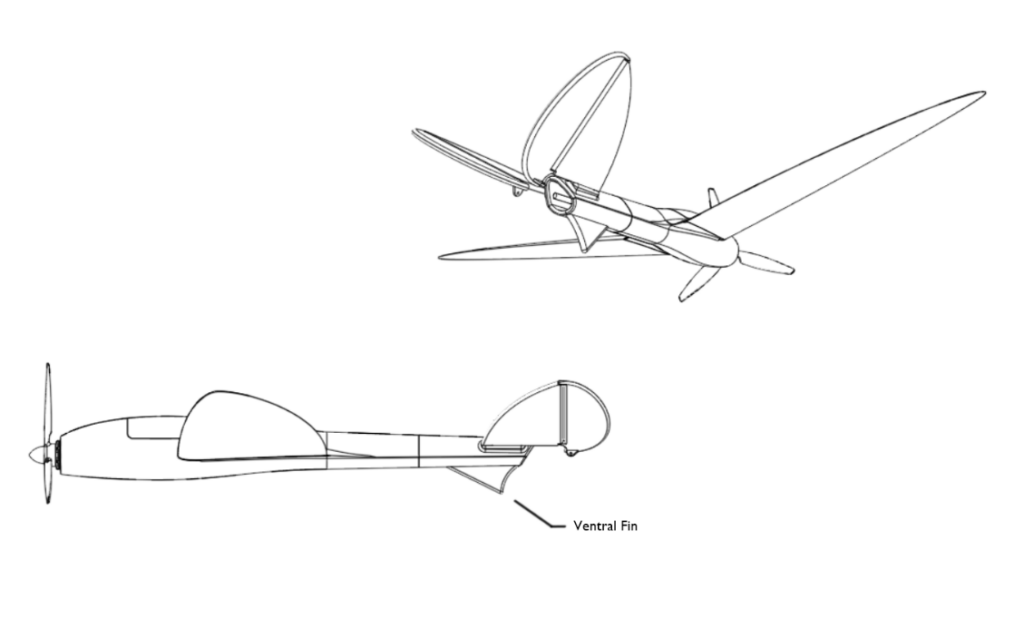

To combat this tendency, I’ve introduced a ventral tailfin to the design. This ventral fin enhances directional stability by providing additional vertical surface area beneath the fuselage. This increase in vertical stabilizing surface helps counteract the adverse yaw movements and stabilizes the aircraft against the Dutch roll tendencies induced by the pronounced dihedral. Thus, the ventral tailfin serves to balance the enhanced roll control achieved through dihedral with improved yaw stability, ensuring smoother and more stable flight dynamics.